In critical sectors such as high‑voltage insulation, home appliances, and electric vehicle battery systems, muscovite mica sheets serve as a proven industrial standard, prized for their reliable electrical and thermal performance.

Next, we will take a closer look at muscovite, to explore its unique structure, how it’s graded, and why it’s preferred in demanding settings.

Muscovite Mica

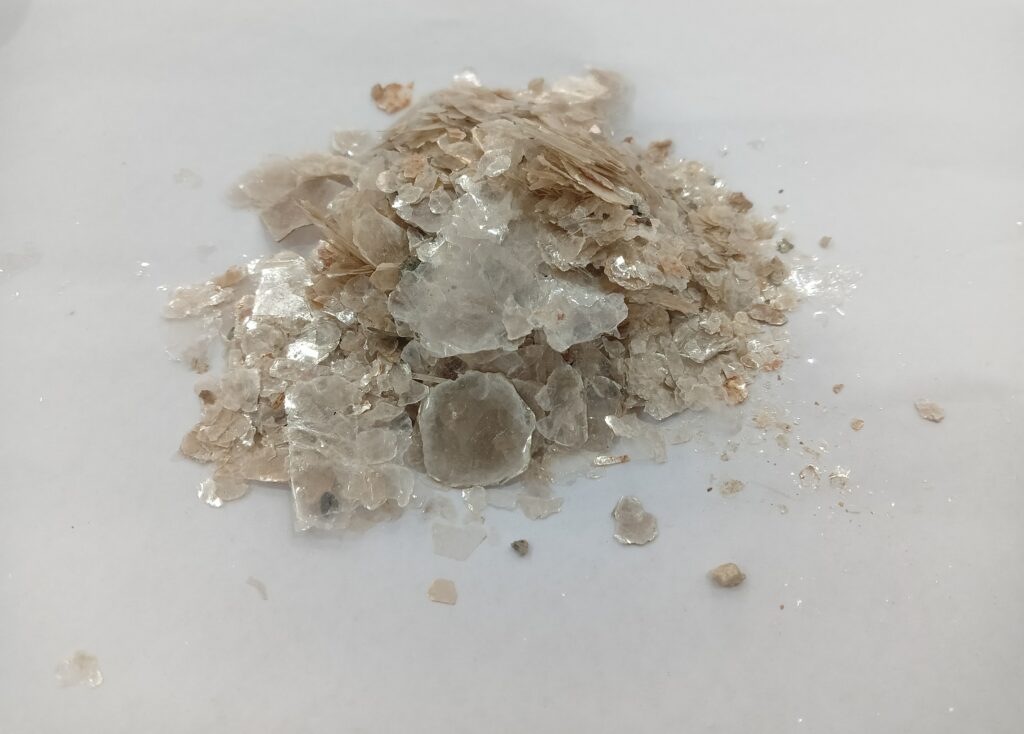

Muscovite Mica, which is a naturally occurring mineral from the mica group, characterized by its layered crystal structure. It consists mainly of potassium, aluminum, silicon, oxygen, and hydrogen. This unique structure allows muscovite to split into very thin, flexible sheets that maintain strength and stability.

These sheets exhibit excellent resistance to heat, electrical current, and chemical corrosion. Muscovite’s thermal stability typically withstands temperatures up to 600°C, making it suitable for many high-temperature insulation applications. Its low electrical conductivity ensures effective dielectric performance.

Thanks to these properties, muscovite finds extensive use in manufacturing insulation products such as sheets, tubes, gaskets, and washers. At MICASHEET™, we transform raw muscovite mica into precision-engineered components tailored for demanding insulation needs.

What Are Muscovite Mica Sheets?

Muscovite sheets are thin, flexible insulation materials made from natural muscovite mica. They have a smooth surface and a light metallic shine. Known for their excellent heat and electrical insulation, these sheets are widely used in sectors including electronics, household appliances, automotive, and industrial heating equipment.

How Are Muscovite Mica Sheets Produced?

Muscovite mica sheets are manufactured by combining high-quality mica paper with silicone resin to create a durable insulation material. The process begins with selecting pure muscovite flakes, which are then mechanically split into thin layers to produce flexible mica paper.

Next, we apply a heat-resistant silicone binder evenly onto multiple layers of mica paper. These coated layers are carefully stacked and aligned to ensure uniform thickness. Then, the assembly undergoes a curing process where heat and pressure bond the layers together, transforming the flexible sheets into rigid, dense mica boards.

After curing, the mica sheets are cooled and trimmed to precise dimensions. Depending on customer requirements, further machining or cutting may follow to produce customized insulation parts. This controlled process using mica paper and silicone ensures excellent electrical insulation, thermal stability, and mechanical strength in the final muscovite mica sheets.

Key Physical and Chemical Indicators of Muscovite Mica Sheets

- Density: Typically ranges from 2.76 to 3.0 g/cm³, making them lightweight for easy handling and installation.

- Melting Point: Around 1370°C, allowing them to withstand extremely high temperatures without melting.

- Dielectric Strength: Usually 10–20 kV/mm, ensuring excellent electrical insulation properties even in demanding environments.

- Chemical Stability: Resistant to most acids (except hydrofluoric acid) and alkalis, ensuring long-term performance in various chemical environments.

- Hardness: Measures 2.5–3 on the Mohs scale, providing a good balance of flexibility and durability.

Key Applications

Now, let’s look at where muscovite shines. In industrial furnaces, it lines walls to keep heat inside. This reduces energy waste and lowers costs. Similarly, in electrical appliances, muscovite parts prevent short circuits. Think of ovens, heaters, or power generators—muscovite keeps them safe and efficient.

Additionally, the automotive industry relies on muscovite. It insulates engine components that reach high temperatures. This ensures parts last longer and vehicles run smoother. From small gadgets to large machinery, muscovite proves its worth daily.

Why Muscovite Beats Other Insulation Materials

Compared to synthetic options, muscovite offers natural advantages. It withstands temperatures up to 700°C, which is higher than many man-made insulators. Also, it’s resistant to chemicals. This means it won’t degrade when exposed to oils, acids, or solvents.

Furthermore, muscovite is lightweight. This makes installation easier and reduces stress on equipment. Unlike heavy ceramics, it doesn’t add unnecessary bulk. For manufacturers, this translates to better efficiency and lower shipping costs.

MICASHEET™: Elevating Muscovite Performance

While natural muscovite is impressive, MICASHEET™ takes it further. Our engineers have enhanced muscovite’s properties to create a product that meets the toughest industry demands. MICASHEET™ retains all the natural benefits—heat resistance, electrical insulation, and durability—while adding consistent quality.

Whether you need sheets for industrial furnaces or precision parts for electronics, MICASHEET™ delivers. It’s designed to fit seamlessly into your production line, saving time and reducing waste.

Choose Muscovite, Choose MICASHEET™

In conclusion, muscovite is a critical material for industries that demand both safety and high performance. When combined with MICASHEET™, it delivers durable and precisely engineered insulation solutions that meet rigorous standards.