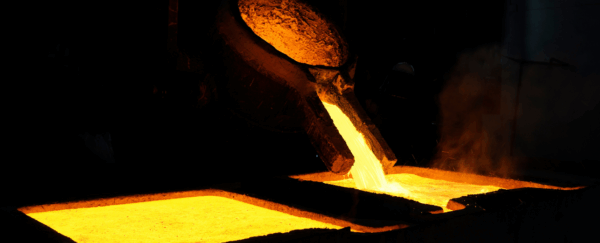

In high-temperature industrial environments like steel production, safety and equipment reliability depend on materials that can perform under extreme thermal and mechanical stress. Mica-based insulation is a trusted choice in the steel industry, valued for its excellent thermal resistance, electrical insulation, and long-term durability in harsh operating conditions.

Where Mica Is Used in Steel Plants

Mica insulation is widely applied across electric arc furnace (EAF) workshops, induction furnace systems, and rolling mill motor rooms, where both heat and electrical insulation are critical.

🔹 Electric Arc Furnaces (EAF)

In the EAF section, mica sheets and tapes are commonly used to insulate busbars, electrode arms, and furnace cables. These areas are exposed to continuous high voltage and extreme radiant heat. Mica provides electrical isolation while resisting degradation from temperatures that often exceed 900–1000°C.

🔹 Induction Furnaces

Inside the melting zones of induction furnaces, mica is used as an interlayer between the coil and the crucible lining. Its role is to:

- Prevent electrical arcing

- Withstand repeated thermal cycling

- Extend the operational life of the induction coil

Flexible mica paper or rigid mica sheets are chosen based on the furnace size and melting schedule.

🔹 Motor and Transformer Insulation in Rolling Mills

Rolling mill operations rely on large motors and transformers running continuously under load. Mica components are used within:

- High-voltage motor windings

- Commutator insulation

- Transformer core wrapping

These help reduce the risk of insulation breakdown and unexpected outages, especially in humid or dusty plant environments.

Why Mica Is Preferred

Mica products—particularly phlogopite and muscovite-based sheets, papers, and tapes—offer the following performance benefits:

- Thermal resistance up to 1000°C (phlogopite)

- Dielectric strength for high-voltage applications

- Non-combustible and flame-resistant

- Dimensionally stable under high temperatures and vibration

- Environmentally safe and asbestos-free

Sizes and Customization We Offer

Micasheet™ supply a wide range of phlogopite mica flanges and rigid mica plates tailored to the steel industry’s needs:

- Phlogopite mica flanges up to Ø900mm in diameter

- Mica plates available in lengths up to 2500mm and thicknesses up to 50mm

- Custom-cut or shaped mica parts available per your technical drawings or specifications

All components are manufactured to tight tolerances and can be adapted to fit various furnace, motor, or power distribution system designs.

Frequency of Use and Maintenance Cycles

In many steel mills, mica insulation is considered a standard material for routine maintenance and shutdown replacements.

- For induction furnaces, mica liners are typically inspected and replaced every 3 to 6 months, depending on melt cycles.

- In EAF applications, mica-wrapped cables and busbar insulation are inspected during major maintenance windows, usually once or twice per year.

- Motor and transformer mica components can last several years, with checks aligned to scheduled electrical maintenance.

Partner with Us

With years of experience supporting the steel and metallurgical industries, our team understands the environmental and operational challenges you face. From initial specification through on-site integration, we provide consistent product quality, engineering support, and timely delivery.

Contact us today to learn more about how our mica insulation products can help optimize performance, improve safety, and reduce downtime in your steel production operations.