Introduction

Mica sheets are versatile insulating materials used across industries where heat resistance, electrical insulation, and durability are critical. From electronics to automotive EV batteries and steelmaking, mica sheets play an essential role in modern manufacturing.

In this guide, we’ll cover the types of mica sheets, their properties, manufacturing process, and applications.

Types of Mica Sheets

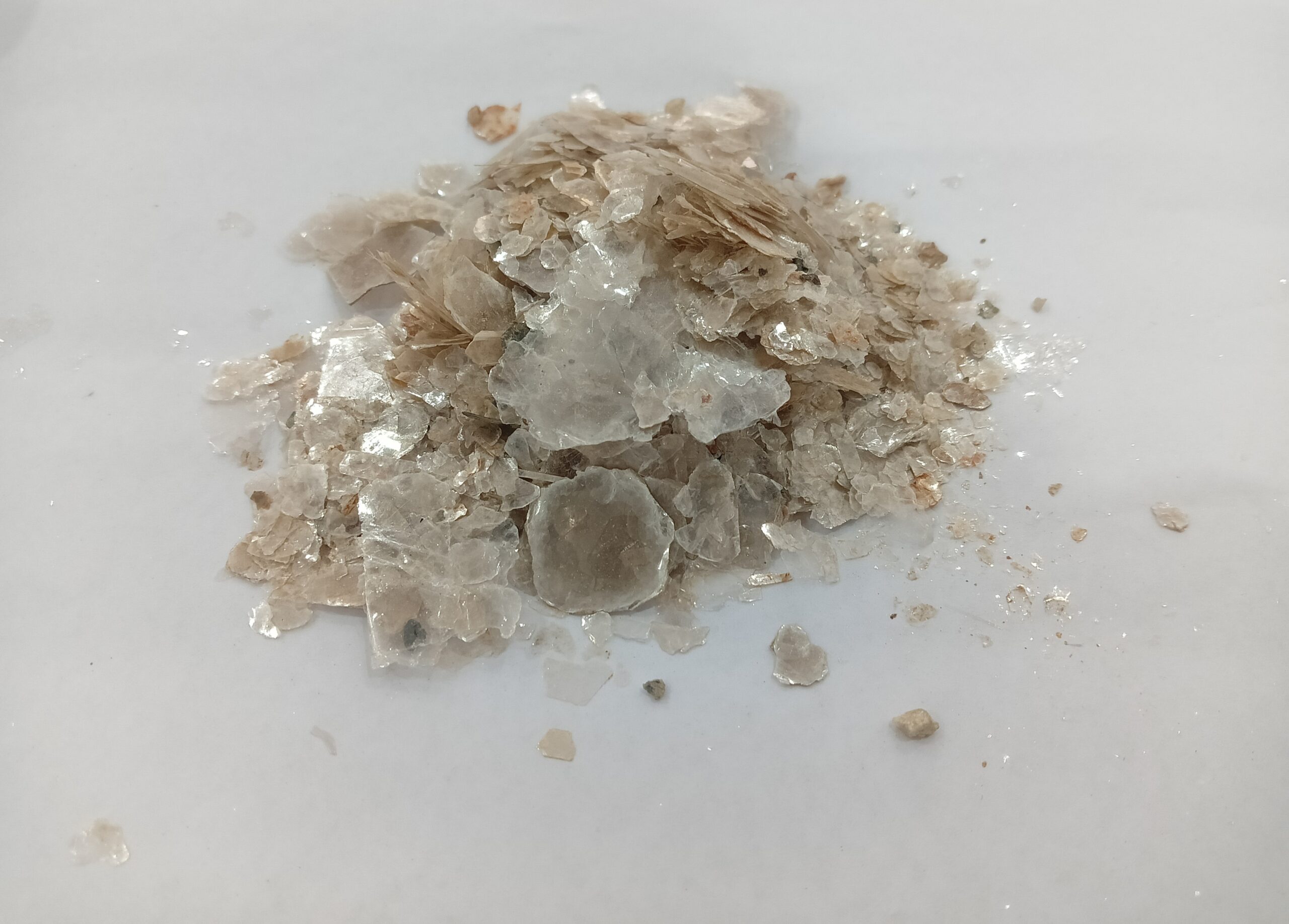

Mica sheets can be divided into three main categories: Muscovite, Phlogopite, and Synthetic Mica.

| Type of Mica Sheet | Appearance | Heat Resistance | Electrical Properties | Cost Level | Typical Applications |

|---|---|---|---|---|---|

| Muscovite | Transparent to silver-white | Up to ~500°C | Excellent dielectric strength | Moderate | Capacitors, electrical insulation |

| Phlogopite | Brown to golden | Up to ~800–1000°C | Stable under high temperature | Higher | Metallurgy, furnace insulation, EV battery safety |

| Synthetic Mica | Transparent, pure | Up to ~1200°C | Superior thermal and electrical stability | Highest | Aerospace, precision electronics |

👉 Learn more about mica products for the battery industry

Rigid vs. Flexible Mica Sheets

Apart from raw material, mica sheets are also categorized as rigid or flexible:

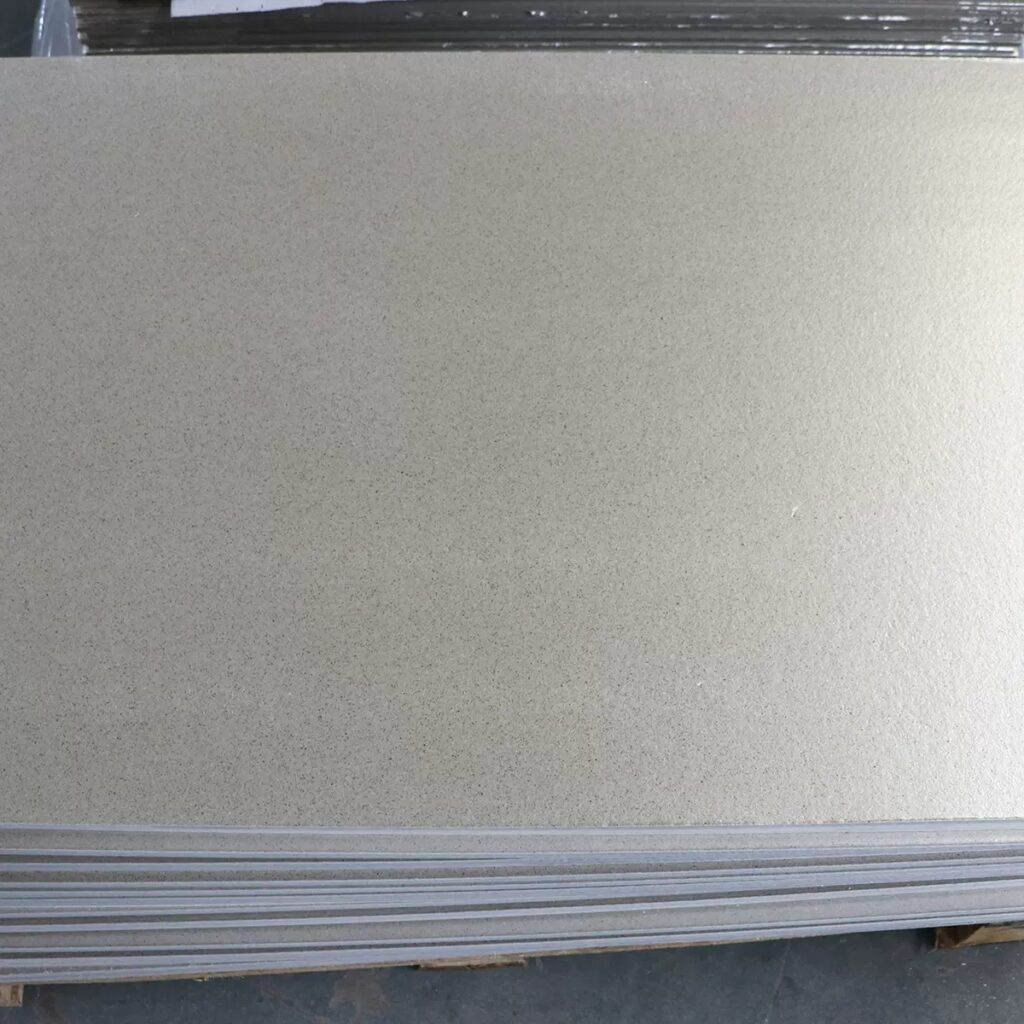

- Rigid Mica Sheets

Produced by bonding mica paper with epoxy or silicone resins. Known for their mechanical strength and high heat resistance. Common in furnaces, heaters, and foundry equipment. - Flexible Mica Sheets

Manufactured using silicone resin binders. They retain insulation while being bendable. Widely used in motor slot insulation, cables, and home appliances.

👉 For example, our mica insulating materials for metallurgy often use rigid mica sheets, while flexible types are preferred in electronics.

Production Process of Mica Sheets

The standard production steps include:

- Splitting and Grinding – Natural mica split into thin layers, processed into paper.

- Resin Impregnation – Mica paper combined with heat-resistant resin.

- Pressing & Curing – Compressed at high temperature to form rigid or flexible sheets.

- Machining & Cutting – Final sheets shaped into gaskets, washers, tubes.

This ensures consistent thermal, mechanical, and electrical performance.

Applications of Mica Sheets

Mica sheets are used wherever thermal protection and insulation are required:

- Electronics – Capacitors, semiconductors, PCB insulation

- Automotive & EVs – Battery thermal barriers, fire protection layers

- Metallurgy & Steelmaking – Furnace linings, molten metal handling

- Household Appliances – Hair dryers, microwave ovens, irons

- Aerospace & Defense – High-temperature insulation materials

👉 Check out our article on mica insulation for EV batteries.

Frequently Asked Questions (FAQ)

1. What are mica sheets made of?

Mica sheets are produced from natural mica minerals (muscovite or phlogopite) or synthetic mica, bonded with heat-resistant resins.

2. What is the difference between rigid and flexible mica sheets?

Rigid mica sheets are hard and durable, ideal for furnaces and heaters, while flexible mica sheets are bendable, making them suitable for cables and motors.

3. Can mica sheets withstand high temperatures?

Yes. Depending on the type, mica sheets can resist temperatures from 500°C (muscovite) up to 1200°C (synthetic mica).

4. Are mica sheets safe for electrical applications?

Absolutely. Mica sheets have excellent dielectric strength, making them reliable insulators in electronics and EV batteries.

Further Resources

For geological insights, visit the Geological Survey of India – Mica Resources.

Final Thoughts

Whether muscovite, phlogopite, or synthetic, and whether rigid or flexible, mica sheets remain a cornerstone in insulation technology. Their heat resistance, electrical insulation, and durability make them indispensable across industries.

👉 Interested in high-performance mica solutions? Explore our mica sheets product page.